CCS And BV Certiciated Ship Marine Rubber Fenders Pneumatic Rubber Fender Factory Price

What is Marine Yokohama Fender

The "Yokohama Type Pneumatic Rubber Fender" was developed in 1958. Progress in the development of such floating pneumatic rubber fenders is closely related to the progress and development of ship technology, and has to continuously cope with progressively larger oil tankers such as VLCC's, ULCC's, large gas carriers, bulk carriers and floating structures.

Floating pneumatic fenders are used world wide for ship-to-ship (STS) transfer operations, terminals, and for all kinds of ships. Since its creation until today, more than millions of fenders have been supplied worldwide both for ship-to-ship and ship-to-dock (STD) operations serving our valuable customers. These fenders play a critical role in the safe operation of ship berthing and mooring.

Our factory

Marine Yokohama Fender types

Marine Yokohama Fender layout

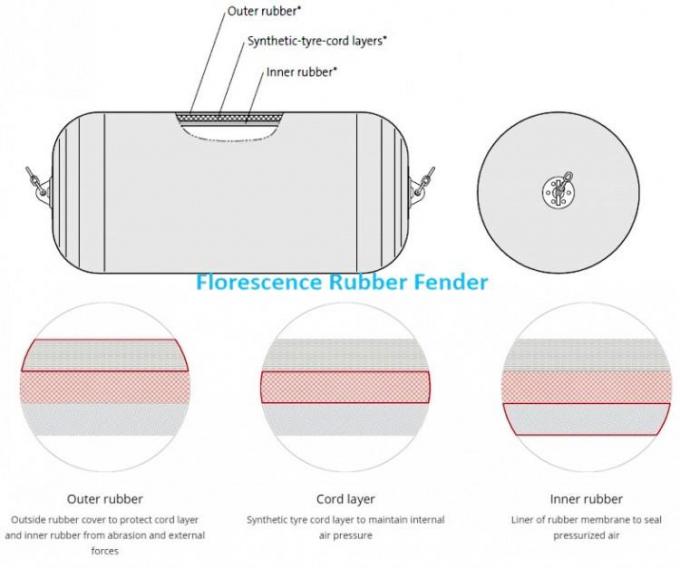

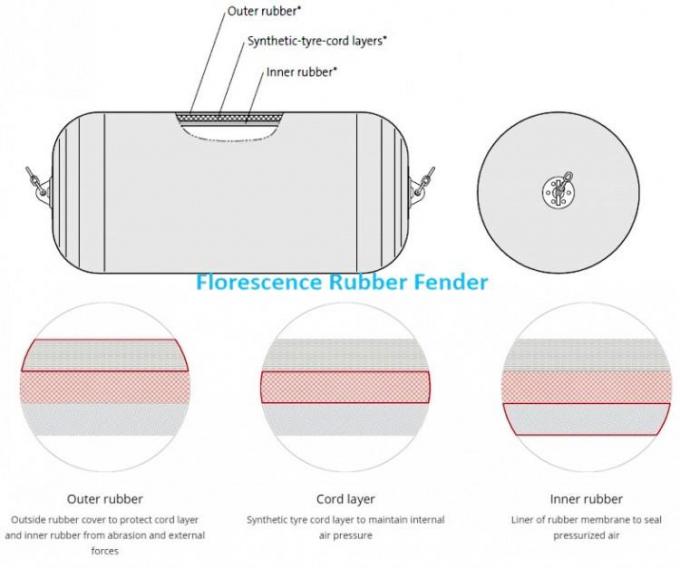

Pneumatic Rubber Fenders are constructed of several layers of strong tire-cord, and are thus resistant to pressure and cutting. The safety factor adopted in the design of this fender is based on accepted theory and has been proven by extensive experimentation.

large-size fenders are equipped with a safety valve to release the inside air in the event of accidental over-pressure.

No Deterioration or Variation in Performance

Pneumatic Rubber Fenders utilize the compressive elasticity of air, therefore

performance deterioration due to fatigue is absent.

Advantages at Inclined Berthing

Pneumatic Rubber Fenders, energy absorption does not decrease at inclined compression up to 15 degrees.

Most Cost Competitive System

The utilization of the compressive elasticity of air provides completely uniform surface pressure on contact, making Pneumatic Rubber Fenders ideal. The surface pressure of the Pneumatic Rubber Fenders is equal to the internal air pressure.

Due to low and uniform surface pressure properties, the Pneumatic Rubber Fenders are popular at LNG-ship terminals.

Soft Reaction Force for Ship and Jetty Structure

The reaction force of Pneumatic Rubber Fenders does not increase sharply, even under excess load conditions. Therefore, the Pneumatic Rubber Fenders perform well in such cases, and protect ships and mooring facilities.

Lower Mooring Forces under Rough Weather Conditions

the reaction force and deflection of Pneumatic Rubber Fenders do not easily reach the maximum because the reaction force increases slowly and allowable deflection is wide. Thus, the Pneumatic Rubber Fenders safely protect ships and mooring facilities even under rough weather.

Marine Yokohama Fender specification:

Specification

D*L(m) |

Initial pneumatic pressure

50KPa |

Initial pneumatic pressure

80KPa |

Applicable

ships

tonnage

(T) |

Body

Weight (Kg) |

R (KN) |

GEA (KJ) |

Body

Weight (Kg) |

R (KN) |

GEA (KJ) |

| 0.5*1.0 |

25 |

64 |

6 |

25 |

83 |

8 |

50 |

| 0.6*1.0 |

32 |

74 |

8 |

32 |

96 |

11 |

50 |

| 1.0*1.5 |

80 |

182 |

32 |

80 |

235 |

44 |

100 |

| 1.0*2.0 |

100 |

257 |

45 |

125 |

335 |

63 |

200 |

| 1.2*2.0 |

120 |

297 |

63 |

165 |

386 |

86 |

300-500 |

| 1.35*2.5 |

165 |

427 |

102 |

226 |

554 |

140 |

300-500 |

| 1.5*3.0 |

315 |

597 |

153 |

370 |

751 |

211 |

1000 |

| 1.7*3.0 |

405 |

639 |

191 |

436 |

830 |

263 |

1000 |

| 2.0*3.5 |

590 |

875 |

308 |

632 |

1138 |

424 |

3000 |

| 2.5*4.0 |

1050 |

1381 |

663 |

1110 |

1815 |

925 |

10000 |

| 2.5*5.5 |

1333 |

2019 |

943 |

1410 |

2653 |

1317 |

10000 |

| 3.0*5.0 |

1880 |

2104 |

1210 |

2155 |

2709 |

1571 |

10000above |

| 3.0*6.0 |

2160 |

2583 |

1485 |

2470 |

3292 |

1888 |

10000above |

| 3.3*4.5 |

2020 |

1884 |

1175 |

2300 |

2476 |

1640 |

10000above |

| 3.3*6.5 |

2700 |

3015 |

1814 |

3080 |

3961 |

2532 |

10000above |

Marine Yokohama Fender in using

Our clients

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!